In the future, a jacket may be able to carry out the functions of a smartphone: Small computers worn on the body are revolutionizing the way we use technology. Würth Elektronik has developed a flexible circuit board called TWINflex-Stretch, opening up completely new possibilities for the field of wearables and other body-hugging applications. This could also be pivotal for medical applications.

Heroically take to the streets

Thanks to its integrated LED lights, the high-tech bike jacket “Sporty Superhero” improves the visibility of bicyclists in the dark. A microelectronic system is integrated into the jacket, containing LEDs, sensors, control elements, an ON/OFF switch, and a rechargeable battery. Despite all of this technology, the jacket is still extremely comfortable thanks to TWINflex-Stretch. It reacts to the bicyclist’s movements, synchronizing them with the LED light pattern on the front and back. The faster the bicyclist rides, the faster the LEDs flash, thus making him easier to see on the dark streets. And the jacket is quite stylish at that: It already received the Red Dot Design Award, one of the most renowned design awards in the world, in the “Design Concept” category.

“Time to take a break!”

The jacket warns its wearer. Using a vibrating alarm, it cautions the jogger that her pulse is too high and that she urgently needs to shift down a gear. So stop, catch your breath, check your vitals – the woman knows how valuable her clothing’s assistance is and uses it accordingly. The jacket not only keeps her warm, it is also a wearable measuring device. It measures bodily functions, records data during the run and even serves as a navigation system. Thanks to artificial intelligence, it is constantly learning more.

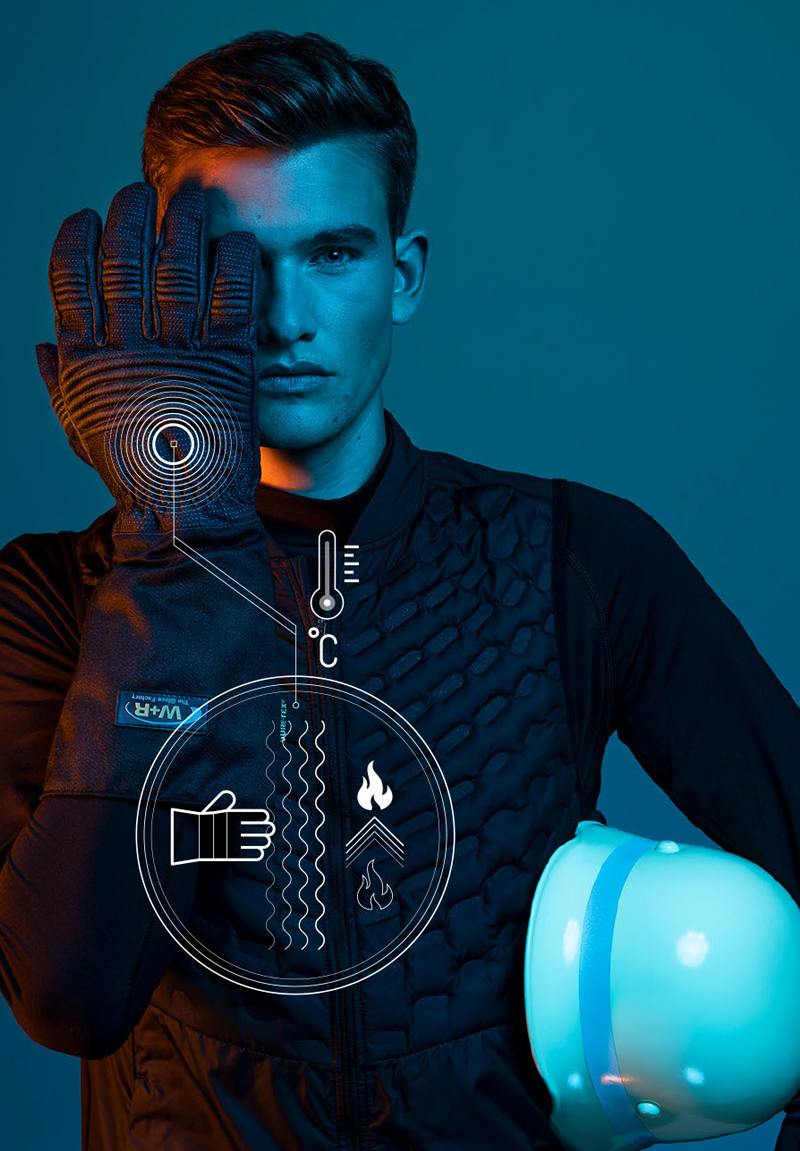

NETWORKED FIREFIGHTING GLOVE

Together with several project partners and the Reutlingen Fire Department, Würth Elektronik has developed a prototype for a networked sensor firefighting glove as part of the joint “GloveNet” project. The prototype works with a temperature sensor integrated into the outer fabric on the palm of the hand. The vibration sensors warn firefighters of a potential flashover – the rapid spread of a flame through the air in a fully developed fire – behind closed doors.

Another clou: When visibility and radio communication are impaired, the gesture communication system integrated into the glove can be used via wireless transmission. Predefined hand movements are detected by acceleration sensors. These movements could communicate, for example, “I’m OK” or “Help me”. These signals are evaluated in the integrated microelectronics by means of special algorithms. The associated radio signals and tactile responses are then transmitted to the other firefighters by the vibration motors. It works similarly to Morse code: The firefighters feel a particular “vibration pattern” through the glove and can decipher the different messages.

An interface between humans and machines

Where and how did this fascination begin? Humans have always entertained the desire to wear technology on their bodies. The abacus ring from China, invented during the 17th century, is considered the first wearable of all time. It served as a technical aid for solving mathematical problems. Other early examples of wearables include, of course, the first wristwatch (early 20th century), the handheld calculator (1967), and the Sony Walkman (1979).

But today’s gadgets can do a whole lot more than these classics. The difference: Modern technologies are integrated into objects such as clothing or accessories. They act as an intuitive human-machine interface while networking with other end devices, such as our smartphone. Furthermore, wearables are becoming increasingly smaller, more powerful, more flexible, and longer lasting – not to mention smarter. Artificial intelligence already allows many systems to learn from their user’s habits.

Navigation for a new generation of “pathfinders”

The Hohenlohe-based company is also enjoying its partnership with the start-up Sensovo from Heilbronn. In this case, the laboratory is cooking up a “guidance system for adventurers”. Once again, the new technology TWINflex-Stretch sparks scores of ideas, whose deliberation would not have been possible without the technology’s outstanding ability to adapt to the wearer’s body: When hiking, climbing, biking, golfing, diving, “and, and, and,” a belt points the way.

TWINflex-Stretch is integrated into it and paired with a smartphone. Athletes are guided by means of vibrations without having to look at the display, concentrating completely on their surroundings and the physical challenge ahead of them. Their field of vision, hands and ears are not needed to navigate.

The belt is adjusted precisely to the respective waistline, just like a conventional belt. If you decide to wear a shirt or a jacket over it, others cannot even tell that you are wearing an intelligent guidance system.

Technology that feels good

There is no lack of creative ideas. Flexible electronic circuits have been part of numerous products for several decades now and are now considered a matter of course. The ongoing trend toward miniaturization with increased functionality in electronics has led to smaller and smaller housings maximizing space in all three dimensions by means of bending, rolling or folding. What are referred to in the technical jargon as “flexible and stretchable circuit carriers” offer many additional geometric design options and features.

“Not every idea can be realized. Reliability and performance have always taken center stage in our developments. Sometimes the technology to be integrated is simply too bulky and therefore not suited for certain areas of application, and miniaturization or supplying power presents further challenges,” says Dr. Alina Schreivogel from the Research and Development department (R&D) at Würth Elektronik. This department, under the leadership of Dr. Jan Kostelnik, together with researchers from the Frauenhofer Institute for Reliability and Microintegration (IZM) quite literally developed a flexible solution to precisely this problem: TWINflex-Stretch. The solution involves a stretchable and flexible circuit board. “It not only serves as a soft basic structure for electronic components but also provides the functions or even an entire application,” explains the R&D team. The R&D manager at Würth Elektronik in Rot am See takes visitors on a journey into the future, describing the basic principles and presenting several exhibits. Whether or not the term “board” should even be used for this is another issue altogether. The mix of epoxy resin and fiber optics typically used as the standard base material is replaced by polyurethane plastic, which is otherwise used for entirely different applications, such as imitation leather or fixture coatings. “We couple this base with yet another stretchable, meander-shaped or wavelike copper structure,” reveals Dr. Jan Kostelnik. This gives rise to an alternative, leaving the rigid, green carriers behind and taking on a novel shape, namely an elastic, soft, skin-friendly carrier that can even be wrinkled and washed. “30 degrees in the washing machine’s gentle cycle – no problem!” explains Dr. Jan Kostelnik.

TWINflex-Stretch more closely resembles a piece of film with an elastic effect, but not a rigid form. As a result, complex electronic systems and sensors can be adapted at will to fit the geometry of the human body, or to suit textiles or other soft and flexible surfaces.

EASY ON THE FEET

Additional applications for the stretchable and washable TWINflex-Stretch circuit board include orthopedics, rehabilitation or sports: For example, Würth Elektronik has installed pressure sensors in the sole of a shoe. TWINflex-Stretch adapts to the foot and therefore does not impair the user’s natural gait or running style.

An example of a specific application: Shortly after an injury or an operation on the foot, it can have a positive effect on the healing process if the foot is not supposed to bear too much weight. The pressure sensors detect when the foot is overloaded and uses a “vibration alarm” to remind the patient to step more lightly.

Award-worthy collaboration

TWINflex-Stretch is already set for serial production and was awarded the 2018 Golden Research Transfer Prize by the Chamber of Industry and Commerce. This prize honors especially successful cooperation projects between the business and scientific communities.

Two products in which TWINflex-Stretch is installed have already made it onto the market: A measuring belt for newborns and a high-tech bike jacket: Information on both of these products, as well as others, can be found next to the photos on these pages.

“Visions are welcome!”

Dr. Alina Schreivogel sums up by saying, “We are proud of what we have achieved.” She feels that the medical industry in particular stands to benefit greatly from the flexible circuit boards. After all, medical applications close to the body require a flexible design that can be shaped to fit the human body. Electronics and sensors in combination with an ultra-flexible TWINflex-Stretch could be attached to orthotics, collars, beds or directly onto the body, in line with the geometry of the respective object. Due to the circuit board system’s stretchability, the system could be put on and taken off several thousand times without damaging the electronic components and features. Furthermore, this innovation is hygienic since it can be washed and sterilized. The tech world has welcomed the TWINflex-Stretch eagerly, submitting corresponding ideas and requests to Würth Elektronik. The researchers and developers have no objections to this. On the contrary, Dr. Jan Kostelnik closes his speech saying: “Although we are often astonished by the creative ideas proposed by our colleagues, when it comes to futuristic technologies, our motto is: Visions are welcome!”

GENTLE DIAGNOSIS FOR NEWBORNS

The Swiss company Swisstom AG has integrated TWINflex-Stretch into a measuring belt for newborns and preterm infants. Due to the hypoallergenic and soft material, the measuring belt can be placed precisely onto the smooth baby skin. It gently measures the baby’s heart and breathing functions, thus making implants and x-ray imaging redundant. The belt took a total of three years to develop: one year of research, one year of prototype development as part of the EU CRADL project (Continuous Regional Analysis Device for Neonate Lung), and one year of product development leading up to serial production.

ROBERT FRIEDMANN

Be it wearables, cars or buildings: more and more “things” are becoming smart. Most of them, like the products on these pages, can assist us in our day-to-day life or help us to live healthier. Such innovations may be daunting to many at first. After all, they collect data, are becoming more intelligent, and get to know us better and better. However, it is up to us humans to use new types of technology for the right purposes and in an ethical manner. That is why we always orient ourselves on our guiding principles throughout the entire Würth Group: We combine visionary thinking and creativity with responsibility and mutual respect. I am convinced that this will be an essential component for long-term success.

THE CYBORGS OF THE FUTURE – A DISCUSSION ABOUT WEARABLES

Read more Interview.